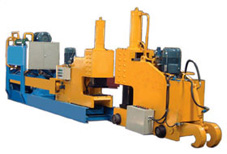

Stretcher

|

|

|

|

|

|

Description:

The machine is operated by two persons, one for the main machine and the other for the random mover. The general operator at the end of the main machine controls it to run, to work or to stop. While the vice operator at the end of the random mover assists the general operator to work. He controls the random small vehicle to go ahead or go back to accord with the length of the aluminum section material. Besides he holds the section material for the general operator to straighten it. The straightening machine holding the section material in two ways, by hand or by machine viz.. That means the way of controlling the jaw at the first period of holding the section material. But in the normal straightening period, the tightening is carried out by the jaw automatically. The bigger the pull is, the bigger the tightness is without loose during the procedure. After the section material is straightened, the lever of the piston stops to work, at the time, little power can loosen the jaw to finish the straightening procedure.

Features:

The function of this device is to do straightening treatment after the finished

1. products are extruded.

2. The hauling force varied from 20 tons to 150 tons.

3. The press down clipping claw design may efficiently clip the shape of the

extruded product to prevent secondary deformation.

4. It has movable lifting hook which may adjust the distance of the stretcher

according to the length of the extruded product to proceed with the

straightening action.

5. The automation and safety device may protect the operator from injury.

6. The head of the large type stretcher which is over 100 tons may also be designed

for rotary type according to the needs of the customers so as to correct the

distortion and deformation caused by big extruded product.

Specifications:

Working pull:15-160T

Equipped with extruder:600~2600T

Oil cylinder size: Ψ110~Ψ350mm

Clamping speed:60mm/s

Return speed:80mm/s