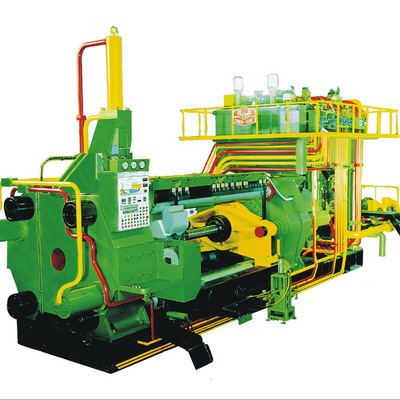

Extrusion press(page1)

Name: extrusion press ABE-500

Description:

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

To aid in understanding the extrusion process think about a Play Doh Fun Factory and how it works. Think of the Fun Factory as the extrusion press, the handle as the ram, the shape bar as the die, and the Play Doh as the aluminum billet. The first step is to choose the desired shape and color. Think of the shape as the die which will be used and the color as the temper and alloy needed. Next, the Play Doh is inserted into the holding chamber and pressure is applied to the handle, which forces Play Doh through the shape. In an extrusion press, pressure is applied to the billet by the ram where the dummy block is attached to the end of the ram stem. When Play Doh begins to emerge, it has effectively been "extruded". The same principles apply to extrusions from aluminum billets but considerably more detailed and sophisticated technology are involved.

Press size determines how large of an extrusion can be produced. Extrusion size is measured by its longest cross-sectional dimension, i.e. its fit within a circumscribing circle. A circumscribed circle is the smallest circle that will completely enclose the cross section of an extruded shape.

The most important factor to remember in the extrusion process is temperature. Temperature is most critical because it gives aluminum desired characteristics such as hardness and finish.

Specifications:

Model:ABE-500

Rated sys pressure:21Mpa

Rated extruding force:5000KN

Center height of main unit:895mm

Dimension of container: Φ75-Φ95×400

main motor power: 55 KW

Overall dimension: 6.3×2.3×2.7

Name: extrusion press ABE-630

Specifications:

Hydraulic pressure: 21Mpa

Force: Main arm:585T/ Faster cylinder:58T

Cylinder back force:35T

Container retaining force:44T

Shear force: 29T

Extrusion speed: 2~8.6mm/s

Container size: Inside diameter:Φ95mm/ length:500mm

Billet size: diameter:Φ90mm/ length:250~420mm

Motor power: ≈62.5KW

Container power: 1.5KW×12=18KW

Operation mode: Manual and single automation

Equipment (L×W×H): 7×2.3×2.8m

equipment weight: 23T