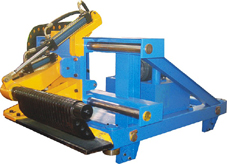

Puller

|

|

|

|

Puller is consist of rectangle railway, puller head, all line slip wire ,main drive and direct current timing device. During the extruding of profile, to reduce bend or flex and high up the up-to-standard rate of finished product, It is necessary to give profile guide &traction ,The machine is driven by DC motor, controlled by PLC, so it characterizes high automatism, easy operation, and stabilized function, Together with auto outlet saw & press machine and post-treatment device. Full linkage production can bi achieved.

Features:

This puller is installed with torque motor to drive the clipping claw

1. The puller, which may be used, on 550 to 3600 tons extrusion press.

The torque motor supplies optional pulling force to meet the requirement of all

kinds of extrusion material.

2. The selected pulling force may be steadily and automatically added to the extrusion

material, which is extruded with different speed. Extrusion type material, cutting

face and kind determine the needed pulling force.

3. This puller provides single or various extrusion lengths after selecting the

pulling force. The pulling speed may synchronize with the extrusion speed of the

extrusion material. The pulling claw has vertical clips to grip the extrusion

material tightly in a level surface.

4. Both the claw and clip may release the extrusion material and return to the

extrusion press surface quickly. The required returning time may be completed

during the idle time of the extrusion press.

5. The shape material extrusion is even, straight and neat, no bending, distortion or

surface scratch.

6. It may provide unified length under single mold, multiple output operation.

7. Reduce straightening time.

8. Reduce worn out for the mould, extend service life of the mould.

9. Save man power.

10. This system includes automatic control and safety equipment to provide reliable

and safe operation procedure.

Specification:

Pulling Force : 0~120Kg

Pulling Speed : 0~100m/min ,adjust with press speed

Returning Speed : 0~200m/min , adjustable

Max .Catcheable Size : 200 mm (W) X 160 mm(H)

DC motor power: 5HP

Hydraulic Motor Power: 1HP

Folder material claw tanks: φ40mmx150mm

Folder feed tank: φ40mmx150mm

Total power: 7.5KW

Supply voltage: Three-phase four-wire 380V/AC 50HZ

Hydraulic disruption of sawing(405 saw 4.5kw) 1set

Traction track length: 34m

Double puller

Name: Double puller |

Name: double tractor |

Name: Forward puller with a flying saw |

Description:

1. Double puller is designed to deliver major advantages over single pullers and even modified single pullers.

2. Two puller heads on the same track, it can seek the die mark and cut profiles on the fly.

3. The power through motor & steel wires driving, controlled speeding & torque.

4. Program control gives you the advantage of several operational modes so you can choose the sequence that best meets your extrusion needs.

Feature:

1. This equipment can be used to draw profile material as well as inequilateral material and small-size sections.

2. It is applicable to set appropriate tractive force in accommodation with various models and sections.

3. The selected tractive force is capable of extruding sections at different velocities stably and automatically. The required tractive force is determined by the cross section as well as the varieties of sections subject to extrusion.

4. The travel speed is synchronous with the speed for extruding sections, and the clipper jaw of the tractor is equipped with vertical clip used to clamp the extruded materials on the plane surface.

5. The clipper jaw and the clip can release the extruding material to return to the surface of extrusion press. the return operation can be completed when the extruding press is at immobile status.

6.It can perform the flat, smooth and straight extrusion of uniform length in the event that one model is used to numerous operations.